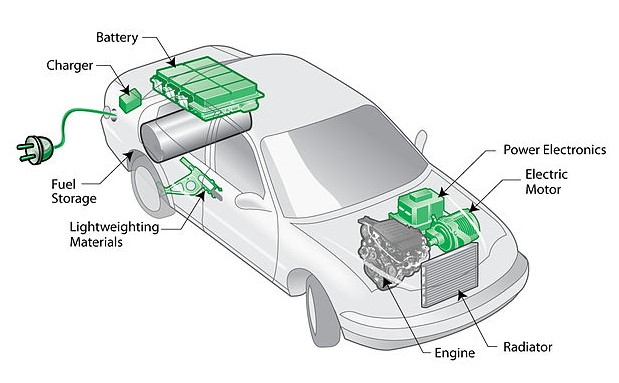

Plug-in Hybrid Electric Vehicles (PHEVs), as a new energy vehicle type positioned between pure electric vehicles (EVs) and conventional fuel vehicles, are characterized by having two power systems: they can run on battery power like an EV and drive on an internal combustion engine like a traditional car. The main difference from ordinary hybrid vehicles (HEVs) is that PHEVs are equipped with larger-capacity batteries and support ev charging via external power sources.

This design provides PHEVs with unique advantages: for short urban commutes, they can rely entirely on electricity, achieving zero emissions and zero fuel consumption; for long-distance travel, they can switch to hybrid mode, effectively eliminating range anxiety. Currently, most PHEVs on the market offer a pure electric range of over 50 kilometers, which is generally sufficient for daily commuting.

However, to fully utilize this flexible driving capability, it is essential to master the correct charging methods. The PHEV charging system is more complex than many people imagine, involving multiple technical components such as the on-board charger (OBC), thermal management system, and high-voltage power management. Understanding these principles not only helps owners use the vehicle more efficiently but also extends battery life and reduces operating costs.

Since PHEVs need to replenish energy from external power sources, a key question arises: household outlets provide 220V AC, while vehicle batteries store DC power; how do these two different forms of electricity interface? This brings us to the core component of the PHEV charging system: the on-board charger (OBC), which converts external AC power into the DC power that the battery can store. It is an indispensable energy conversion hub in the charging process.

The On-Board Charger (OBC) is the central component of a PHEV's charging system. Its function is simple yet crucial: converting external alternating current (AC) into direct current (DC) that the battery can store. Whether using a household 220V outlet or a dedicated charging station, the current must pass through the OBC before entering the battery.

The presence of the OBC enables home charging for PHEVs. Owners can simply use the portable charging cable provided with the vehicle and plug it into a regular household outlet to recharge. This convenience is one of the key factors attracting consumers to PHEVs.

During operation, the OBC faces significant thermal challenges. Power conversion inherently generates heat, and the faster the charging speed, the more heat is produced. Without adequate cooling, high temperatures can reduce OBC efficiency and shorten its lifespan.

PHEVs have more complex thermal management systems than pure EVs. In ordinary hybrids, electricity primarily comes from the engine driving a generator or from regenerative braking, with relatively low power levels. PHEV OBCs, however, must coordinate with external chargers, high-to-low voltage DC/DC converters, motors, and inverters. These components often share a series-cooled system, increasing demands on the cooling system.

Designing the OBC requires precise calculations of heat generation and flow resistance under different charging powers. OBCs supporting high-power fast charging require larger radiators and coolant circulation systems to ensure safe operating temperatures under heavy loads.

PHEV batteries are usually smaller than those in pure EVs, creating a design trade-off: either choose lower charging power with longer charging time, or higher charging power for faster charging. Different choices directly affect OBC cooling requirements.

Low-power slow charging has lower cooling requirements and lower system costs but may take 6-8 hours or longer to fully charge. High-power fast charging can significantly reduce charging time (usually 1-2 hours) but requires more advanced cooling systems and higher-spec electronic components, increasing costs.

Currently, most PHEVs on the market use OBCs rated at 3.3kW or 6.6kW. The 3.3kW version works with a standard household outlet, is slower, but cheaper. The 6.6kW version doubles the charging speed but generally requires a dedicated charging station and a more robust cooling system.

Since the OBC is the core energy conversion component and its cooling design determines the stability and lifespan of the charging system, the most practical question for owners is: what are the available ways to charge a PHEV? What are the characteristics and precautions for each method? Below, we detail the two most common PHEV charging methods: household 220V power and dedicated charging stations.

Charging via a household 220V outlet is the most convenient and commonly used method for PHEV owners. The operation is straightforward: use the portable charging cable that comes with the vehicle and plug it into a standard household 220V single-phase AC outlet to start charging.

Key Precautions:

- Waterproof outlet: Charging may take several hours, and rain could occur. Waterproof outlets prevent water ingress that could cause short circuits or electric shocks. If the parking spot is outdoors, install a dedicated waterproof outlet.

- Sufficient circuit load: Although household charging power is modest (usually 2-3kW), the wiring must handle continuous load. Older homes may have aged wiring, posing safety risks. A professional electrician should inspect and upgrade circuits if necessary.

- Reliable grounding: The ground wire is critical for safety in case of leakage. Do not use ungrounded two-prong outlets or adapters.

- Long charging time: Household 220V charging typically takes 5-8 hours depending on battery capacity. Charging overnight during off-peak hours is recommended to save money and ensure vehicle availability the next day.

Dedicated charging stations offer higher efficiency, ideal for public parking lots, workplaces, or highway service areas. Stations supply AC or DC power (depending on type) and connect to the vehicle via a dedicated interface.

- Advantages: AC stations usually provide 7kW or more, reducing charging to 1-2 hours. Some DC fast-charging PHEVs can charge even faster. Stations feature overvoltage, overcurrent, and leakage protection, and are typically installed in dedicated spaces. Many stations support card, QR code, or app activation and allow real-time monitoring of charging progress and costs.

- Usage Recommendation: While household charging is convenient and economical, PHEV owners are advised to periodically use dedicated stations. Fast charging saves time and enables more complete charge-discharge cycles, maintaining battery activity. For owners without a private parking spot or home charging, public stations are essential.

Whether using a household outlet or a dedicated station, PHEV charging essentially converts external energy via the OBC into the high-voltage battery. Why do PHEVs use high-voltage systems of 300V–400V or more? This high-voltage design improves charging efficiency but also raises safety concerns. Balancing efficiency and safety is central to PHEV electrical design.

Modern PHEVs generally use 300V–400V or higher systems for efficiency. According to the power formula P=UI (Power = Voltage × Current), increasing voltage reduces current for the same power. Lower current reduces heat loss in wiring (Q=I²Rt), improving overall energy conversion efficiency.

For example, driving a high-power air conditioning compressor with a traditional 12V system requires extremely high current, thick wiring, and causes significant heat loss. High-voltage systems reduce current, allow thinner wires, and increase efficiency. Similarly, high-power actuators such as electric heaters and water pumps benefit from high-voltage operation.

Voltages above 300V exceed human safety limits (36V), so leaks or insulation failures can cause serious electric shocks. PHEVs employ multiple safety measures:

- Insulation monitoring: Constantly monitors high-voltage lines; alerts and disconnects if insulation drops.

- High-voltage interlock: All HV connectors have interlocks that cut power if removed or loosened.

- Crash disconnect: In collisions, the airbag controller immediately shuts down HV power to prevent fire or shock.

- Maintenance switch: Allows manual disconnection of HV power during service for technician safety.

These protections increase vehicle cost, as high-voltage components require precision manufacturing and strict quality control, but they are essential for occupant safety.

In practice, some owners may rarely charge, using the PHEV mainly as a conventional fuel vehicle, while others may only drive electrically to save fuel. Are these extremes feasible, and what are the consequences? Does gasoline in the tank expire?

Many owners with inconvenient charging access may never plug in. Technically, this won't immediately damage the vehicle, as PHEVs have robust self-protection. When battery charge drops to a certain level (usually 15%-30%), the system triggers "battery preservation mode," where the engine drives the generator to recharge the battery, preventing over-discharge.

Increased fuel consumption: Engine-driven charging (“oil-to-electric”) is inefficient, sometimes exceeding fuel use of conventional vehicles.

Battery degradation: Lithium batteries suffer if kept at high or low states of charge; regular cycling maintains battery health.

Loss of environmental benefit: Without charging, short-distance EV driving and emission reduction are lost.

For mostly electric users, gasoline in the tank may degrade over time. Ethanol gasoline lasts about 1 month, and regular gasoline about 3 months. To mitigate:

- Only add a small amount (50–100 yuan worth) for backup.

- Drive in hybrid mode every 1–2 months to consume old fuel and maintain the engine.

- Inspect fuel system regularly; replace gasoline if starting or power issues appear.

PHEV charging systems are complex, involving power electronics, thermal management, and high-voltage safety. Understanding OBC operation, mastering proper charging, and knowing high-voltage safety designs help owners maximize the “electric and fuel” advantage. For daily use, create charging opportunities and maintain a regular charging habit. This reduces costs, emissions, and keeps the battery healthy, extending vehicle life. Also, monitor fuel shelf life to avoid degraded gasoline affecting engine performance. With continued improvement of charging infrastructure and battery technology, PHEV usage will become increasingly convenient. Mastering these charging principles allows you to fully enjoy green travel in the new energy era.